Description

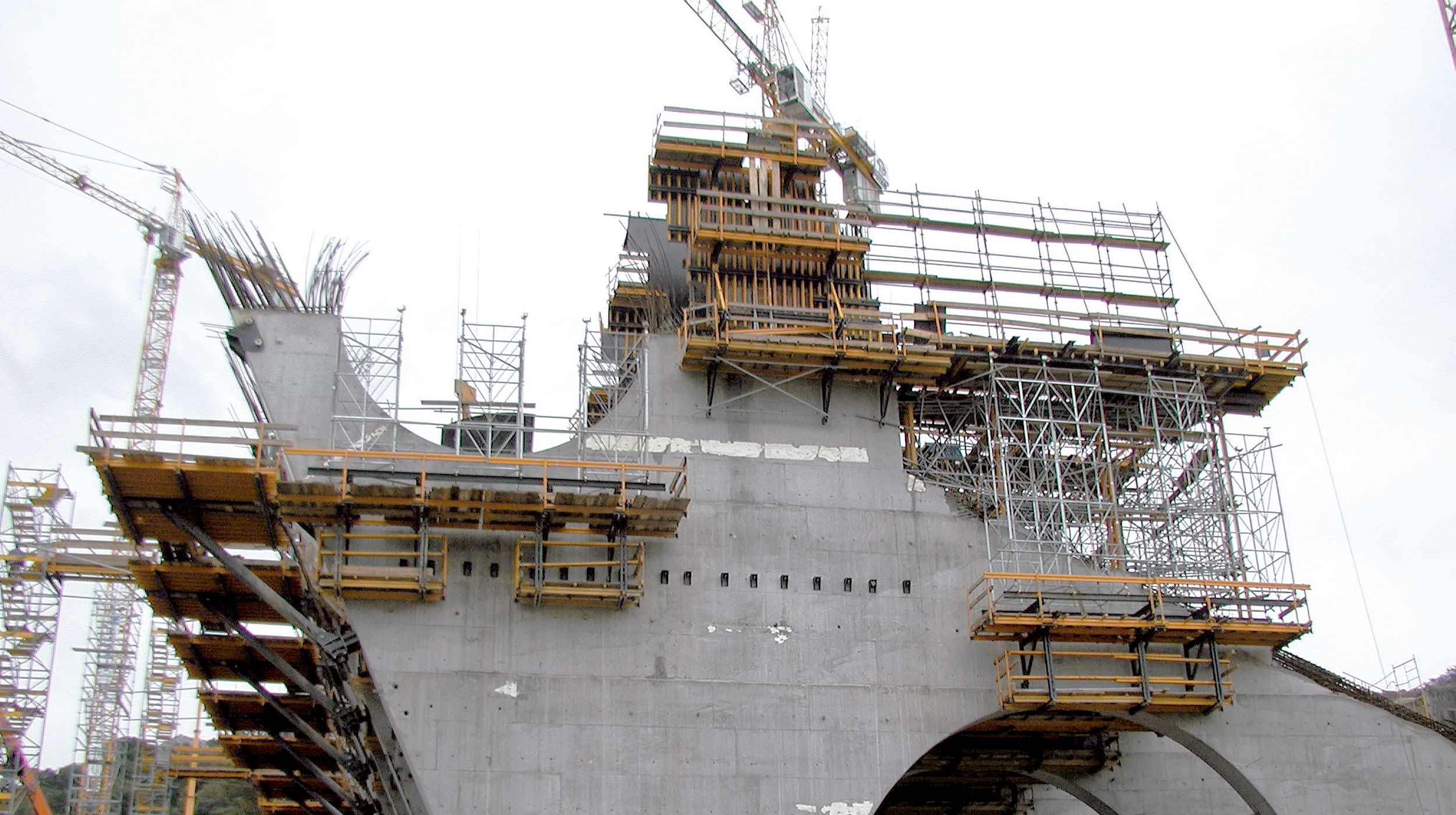

Planned over a quarry in disuse, the Soccer Stadium has a capacity for more than 30,000 spectators. It consists of two stands, "Nascente" and "Poente," on the sides of the playing field, and 3 circular galleries through them, as well as two underground parking levels. Its roof is made up of a weave of cables, with a 220 m, that joins the two grandstands.

ULMA Solution

With a height of 50 m, a width of 1 m, and a distance between axes of 7.5 m, 16 walls were set up to support the stand slab and as a system to join the stadium roof. These walls were executed with ENKOFORMV-100 and Conventional Climbing Systems, in 5 m pourings. In areas with transversal lightening, the panels were supported on shoring towers.

At a height of 30 m, the front side of the walls have a 13 m cantilever executed with the mentioned system, as well as the bulkheads with G Heavy Duty Bracket, due to the sloped wall. The ENKOFORM V-100 formwork displayed its versatility and efficiency in resolving the multiple geometries of this construction project.

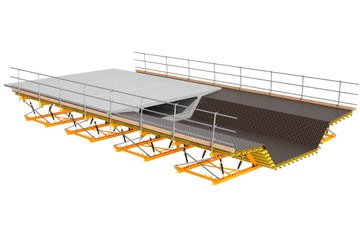

The slabs, with an average thickness of 0.35 m and a width of 6.50 m, were carried out with ENKOFORM HMK and shoring system, sometimes over lower intermediate slabs, already completed and conventionally propped. In areas where shoring was not possible, profiles were assembled over brackets fixed to the anchors placed in the wall.

The 6 m long side slabs with cantilevers and a variable thickness between 30 and 60 cm were resolved in the following manner: in the north side, using 20 m shoring towers in the lower area, increasing in height as the slabs and stairs were shored, and in the south, with a 20 m high T-500 gantry shoring, on which a continuous shoring reaching 24 m was set up.

The concrete beam, responsible for the upper tying of the walls and the anchorage of the roof suspension cables, was made with ENKOFORM HMK, as bottom and side formwork, over brackets and COMAIN vertical formwork for the stopends.

The 6 m cantilever, on each end, was executed with ENKOFORM HMK suspended from 4 trusses. The towers that acted as support for the formwork of cantilever slabs were used as platforms.In this way, the use of material was optimized, since it was continuously re-used.