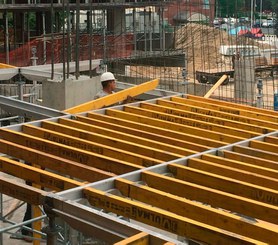

FORMADECK is a post, joist and drop head handset shoring system designed to maximize labor productivity and reduce formwork cycle time.

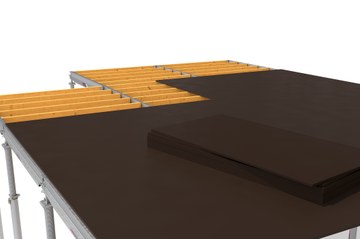

The FORMADECK shoring system provides a high level of productivity through the use of 8’ x 8’ and 8’ x 6’ grid, easy to handle components, and drop heads for early retrieval and cycling of joists, girders and plywood. FORMADECK slab formwork allows fast system assembly and stripping, saving time and minimizing on-site material requirements.

The ability to install the system from the ground with simple light-weight components results in added safety and overall ease of use.

Applications:

- Projects where regular grid system will speed productivity due to flat plate with long runs and limited number of drop beams.

- Projects where fast cycle time require a drop head system.

- Projects where shoring heights are under 20 feet and can be shored using a grid system.

- System accommodates soffit heights from 6’-6” to 14’-1” with available EP Props and from 5'-5" to 20’-8” with available ALUPROPs

- Can support a 10” thick concrete slab on an 8’ x 8’ grid and a 14” thick slab on a 6’ x 8’ grid throughout the entire post range

- Can support slabs up to 36” thick throughout post range with standard equipment

- The 8’ x 8’ and 6’x 8’ grid patterns reduce the amount of post shores required, reduce installation time, and are well suited for the use of 4’x 8’ plywood sheets

- Fast cycling of equipment by means of fast-actuating drop head. Drop Head allows for early retrieval of joists, girders and untrapped plywood while loaded post shore remains in place

- Joists and girders are individually identified by length to facilitate identification on the job site

- Hammer is the only tool needed to install and strip system

- Productivity

- Drop head design allows the majority of the system to be cycled for next pour reducing on site equipment needs (joist, girder and grid joist). Drop head mechanism allows props to remain as re-shores

- Provides a high level of productivity through the use of 8’ x 8’ and 8’ X 6’ grid patterns

- Reduces labor needed to erect and disassemble system. 2 workers can erect up to 588 ft2 per hour of FORMADECK on an 8' x 8' grid

- Easy to use

- Fewer components simplifying erection/assembly procedure

- The drop head allows for changing direction of girders and joists by 90º. This characteristic makes the system versatile and simplifies infillings

- Easy jobsite handling of materials with provided racks and carts

- Safety

- Formwork system is erected and dismantled from beneath the slab to be poured

- Lightweight system components provide overall ease of use and results in reduced worker fatigue, injuries and down time

- Drop head mechanism minimizes hazard of falling plywood during stripping

- Cantilever girders with post sockets facilitate safe erection of perimeter formwork enabling installation of the required handrail system. This assembly is secured with a hold down bracket in order to avoid cantilever girder overturning